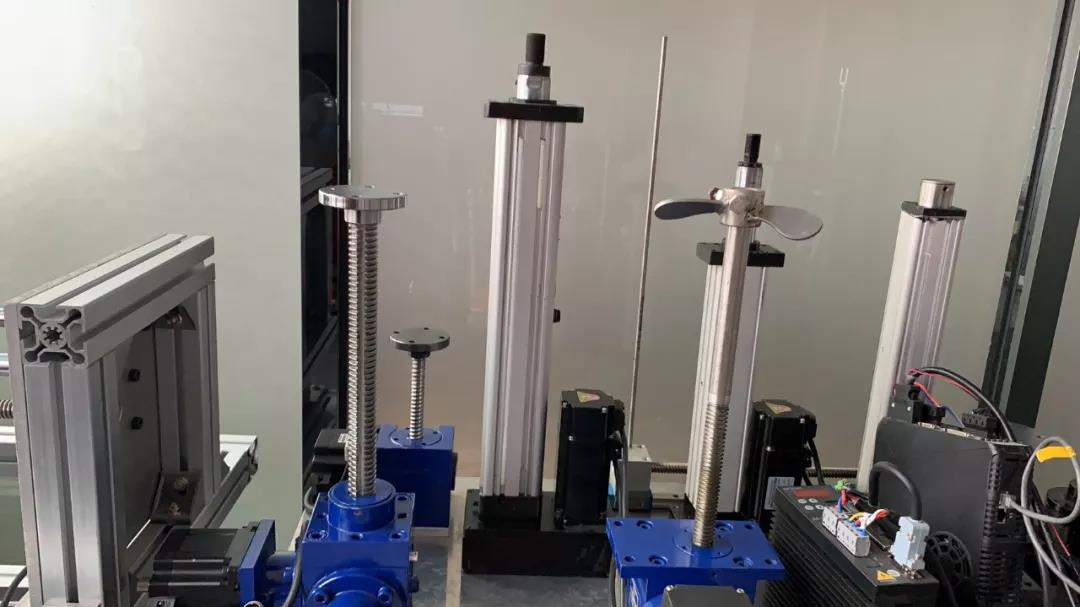

107.NOSEN mechanical and Electrical secrets for you! What is the difference between the use of a screw lift and a servo motor cylinder?

release time:

2021-03-11 17:00

Screw jack and servo electric cylinder can realize mechanical movement into linear movement back and forth, in comparison, due to the servo motor and servo electric cylinder screw jack combination makes the servo electric cylinder thrust, speed and position control is more precise, therefore they are widely used in modern digital and network technology, and other fields, can be programmed control, the cost is relatively high.

Screw jack is widely used in machinery, metallurgy, construction, chemical, medical, cultural and health industries, according to a certain procedure to accurately control the height of the promotion or promotion, can be driven directly by electric motor or other power, but also manual.

1. Screw jac must be done before using the screw lift to check whether the lifting is normal.

2. The load of the table is not greater than the rated value, and it cannot be shaken violently.

Lubricating oil (or grease) must be added before the worm gear screw lift is started to ensure the service life of the equipment.

Is the servo motor and servo electric cylinder screw integration design of modular products, the servo motor rotation movement into linear motion, at the same time to best advantage - servo motor speed control precision, precise control of revolution, accurate torque control into - precise speed control, precise position control, accurate thrust control, high precision linear motion series of revolutionary new product.

- the electric cylinder is a precision mechatronic integration product, prior to use to read the precautions and related motor, driver instructions, and pay attention to the use. The electric cylinder shall not be disassembled without the permission of the electric cylinder manufacturer. Especially the outside of the electric cylinder of each screw.

2. The motor and the servo motor cylinder are connected by high strength synchronous belt, and the tension is adjusted. Therefore, the motor cannot be disassembled at will, otherwise the synchronous belt will be damaged due to improper tension.

3. When the servo motor driver is used for a long time, attention should be paid to ventilation and heat dissipation to avoid burnout.

Dongguan NOSEN Electromechanical Technology Co., Ltd. is a professional r & D, production, sales and service as one of the mechanical and electrical enterprises, combined with decades of experience in transmission design, independent research and development of ball screw elevator, cross steering, servo electric cylinder and other products. Every employee of Luosheng Machinery &Electrical Co., LTD is also constantly improving their technical level to produce more high-quality products, so that more users can recognize the quality of their products.

Latest News

Exist for electromechanical technology and develop for intelligent transmission!

Address: Room 2106, Building 1, Fenghui Plaza, No. 1 Hongyi Road, Nancheng Street, Dongguan City, Guangdong Province

Copyright © 2022 Dongguan NOSEN M&E Technology Co.,Ltd Powered by www.300.cn 粤ICP备10088235号