Product Center

收藏

对比

编号 :

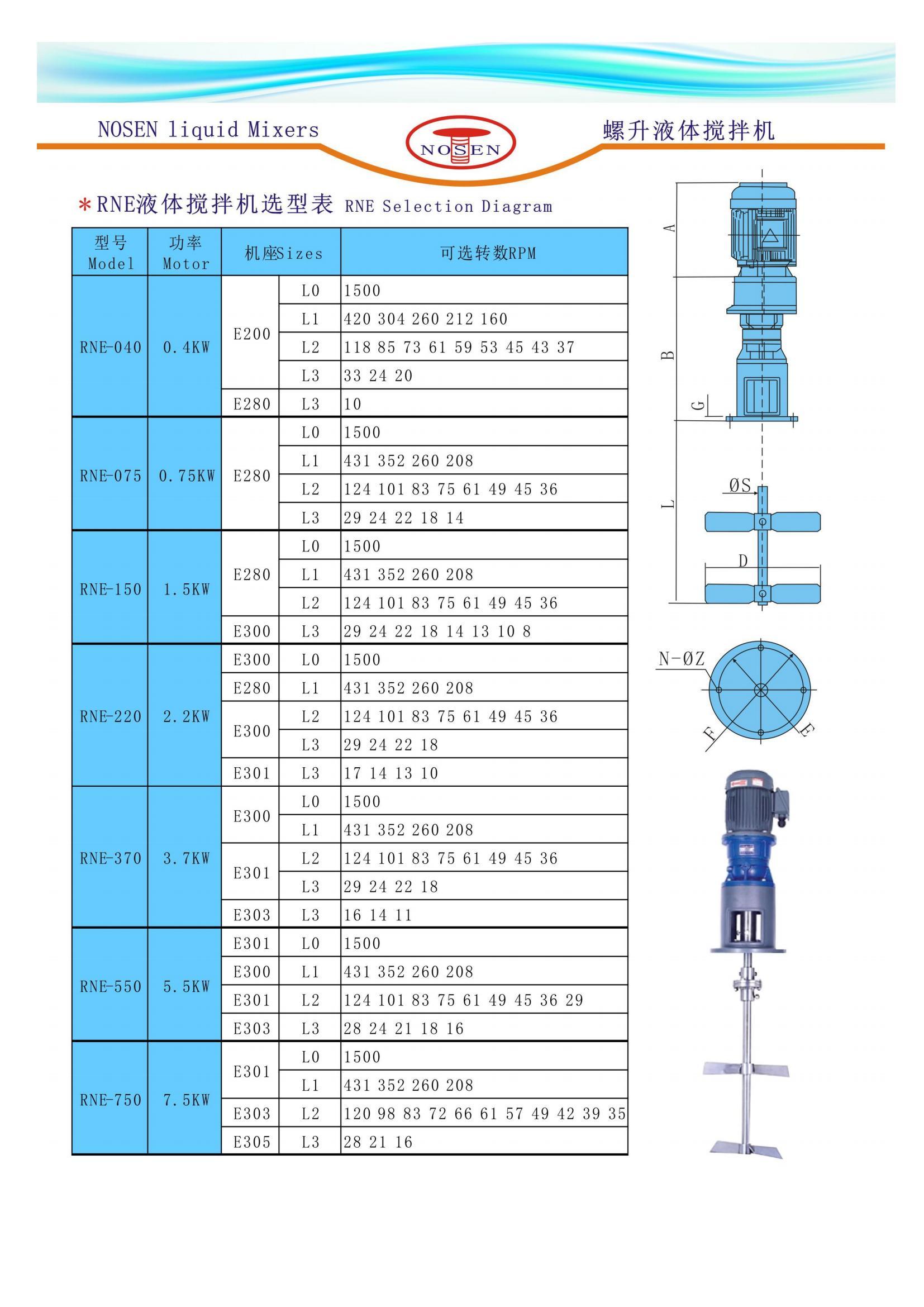

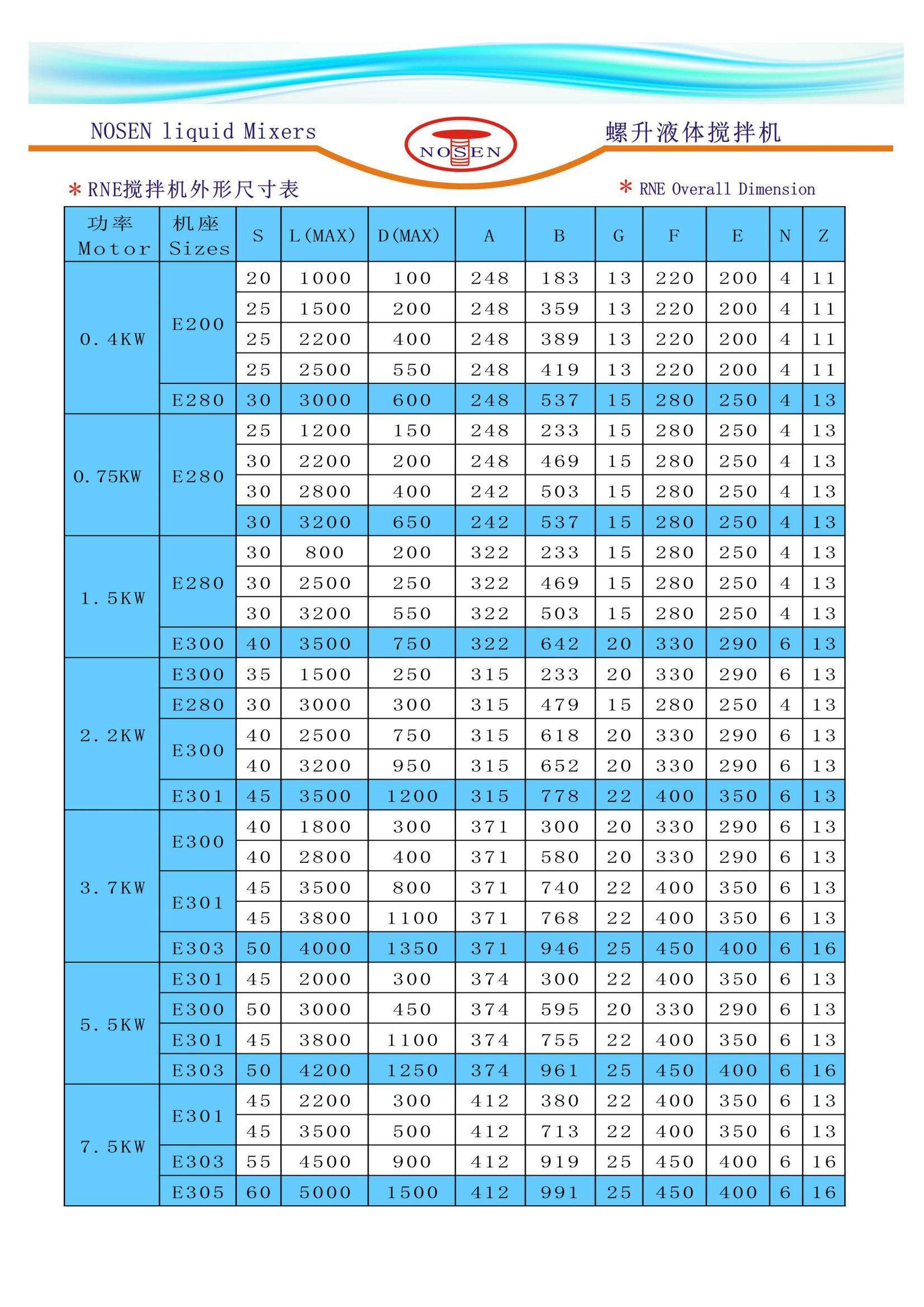

Liquid mixer RNE

Liquid mixer RNE

零售价

市场价

重量

kg

库存

隐藏域元素占位

- Model

- Selection

- Specifications

- Size

-

Installing from top: The agitator rod should be stuck into the tank for liquid mixing from the right above the tank center or deviate the tank center, creating the up and down convection and mixing between the liquid and agitator blades. You should consider the phenomenon generated by the liquid and blades while mixing if the rod is installed from the center above the tank, forcing the liquid and blades are relatively stable. Especially, the faster the agitator is mixing, the easier the situation will be present. You should equip with blocking board from the inside of the tank to reduce the revolving phenomenon for such situation. The size of the blocking board is determined by the density or viscosity of the liquid and mixer speed. After adding the blocking board, the resistance of the liquid mixing will be increased so the motor power should be enlarged. The mixing efficiency is the lowest for this installation method. The mixing effect will be better if you stick the rod deviate the tank center from above. No resolving phenomenon. In addition, you don’t need to equip with blocking board to prevent the resolving problem. We suggest to place bearing to fix the rod if its length is over 2 meters, extending the lifespan of the agitator.

Installing from the side: This installation method is mostly used for large size of tank. It is effectively prevent the resolving problem from happening. The agitator rod should be stuck from the side of the tank. We suggest to reserve an angle less than 10 degree for the agitator side installation to the tank instead of the agitator installed vertically to the side of the tank. Please pay attention to the even performance of sealing. A ring of seal is required if necessary. Bearing is required if agitator shaft is too long.

The size of agitator blade is determined by the size of tank and form of liquid as well as the power of motor. The layer of blade is various from the shape of tank and the volume of liquid. There are different kinds of blade, such as double plat paddles, impellers, detachable four plat paddles and open paddles. In the fact of selecting blades, you should consider a range after calculating the integrate factors and choose the closest size. In order to fabricate easily, the blades should be enlarge or shrink by 50mm. It is all available for the multiple diameter size of 50mm.

The stainless steel material of the agitator is for rod and blades. You can decide to choose whether SUS304 or SUS316 by the PH of the liquid.

-

-

Other Products

Heavy Duty Machine Screw Jack RNF series

Bevel Gear Screw Jack RNS series

Need service or support? Welcome to enable the online message function, we will give you timely feedback and provide you with suitable solutions.

Exist for electromechanical technology and develop for intelligent transmission!

Address: Room 2106, Building 1, Fenghui Plaza, No. 1 Hongyi Road, Nancheng Street, Dongguan City, Guangdong Province

Copyright © 2022 Dongguan NOSEN M&E Technology Co.,Ltd Powered by www.300.cn 粤ICP备10088235号